| 工作原理 | 旋流 |

|---|---|

| 规格 | 600*6000型 |

| 适用物料 | 颗粒状 |

| 干燥介质 | 空气 |

| 湿物料运动方式 | 固定床式 |

| 型号 | KYQL400 |

| 加工定制 | 是 |

一、 产品型号及适用范围

1、 型号名称:

MQG系列脉冲气流干燥机

适用范围:

KYQL系列气流干燥机适用于机制木炭业的粉状、小颗粒状物料的干燥,是目前我国机制木炭加工中理想的物料干燥设备。适用于各中、小型木炭厂配套使用。该烘干系统吸收了本公司成熟技术优化设计而成,具有产量高、能耗低、干燥快,干燥效果好、回收率高等优点。

工作原理:

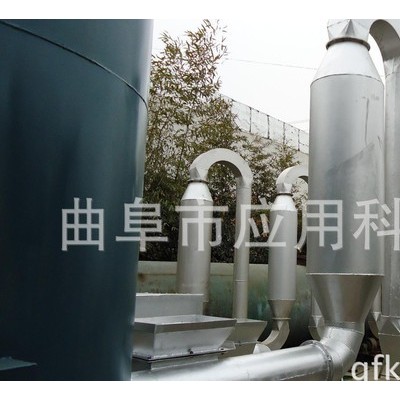

该机主要由热风炉、U型脉冲管、风机、刹克隆等部分组成,在引风机作用下热风和物料同时被吸入管道中。含水物料悬浮于高速热气流中,通过干燥管道。由于脉冲管作用,气流发生旋转,使物料不断翻滚,增大了与热气流的传热交换,提高了热效率。物料在3-5秒时间内即完成干燥,被旋风分离器及袋式收集器收集。回收效率高达98%,可连续干燥大量物料。

主要参数:

| 型 号 | 产量 (Kg/h) | 功 率 (KW) | 备注 |

| KYQL400 | 400-600 | 7.5 | 含炉子 |

| KYQL600 | 800-1000 | 18.5 | 含炉子 |

| KYQL900 | 1500-2000 | 45 | 提供炉子图纸 |

标称型号产品及根据用户要求加工定做,材质可以选碳钢、铝合金、不锈钢等。

地址:山东曲阜市春秋东路科创楼 QQ:952096812

手机:13854752506 、 13375471858 电话:0537-3191653

网址://www.keyang1988.com E-mail 952096812@qq.com